IoT Sensor Technology: A Deep Dive

Modern industrial systems increasingly depend on IoT sensors as core components of automation infrastructure. These compact devices serve as sensory organs for networked equipment, capturing environmental data and relaying it to centralized processing units. Their unassuming appearance belies their critical role in everything from residential automation to large-scale industrial operations. By continuously tracking variables like thermal conditions, force measurements, moisture content, and illumination levels, they provide the raw data necessary for responsive system adjustments.

Sensor technology continues its rapid evolution, with notable progress in three key areas: size reduction, power management, and data transmission standards. These improvements yield more dependable, cost-effective solutions suitable for diverse applications. The proliferation of wireless sensor arrays has particularly expanded monitoring capabilities in hard-to-access locations. These technological strides are enabling progressively more sophisticated automation networks with enhanced decision-making capabilities.

Applications Across Diverse Industries

IoT sensing solutions have penetrated nearly every sector, fundamentally altering established practices and creating novel opportunities. Agricultural operations employ them to track soil hydration and plant vitality, enabling data-driven irrigation and nutrient management. Urban centers implement sensor grids to optimize vehicular movement, assess atmospheric conditions, and enhance community safety protocols. Industrial manufacturers incorporate them into equipment monitoring systems to anticipate maintenance needs.

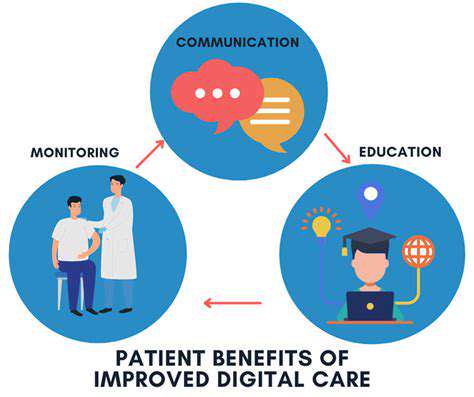

The medical field has adopted these technologies for continuous patient observation, facilitating early intervention strategies and improved treatment outcomes. This widespread adoption across varied domains demonstrates the adaptability of sensor networks and their capacity to drive operational improvements across multiple sectors.

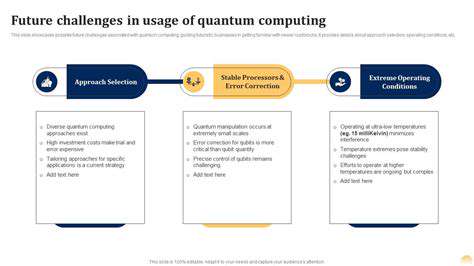

Challenges and Future Trends

While offering substantial benefits, sensor networks must overcome issues concerning data protection, individual privacy, and system scalability. Establishing robust security frameworks for transmitted and stored sensor data represents a non-negotiable requirement. Successfully addressing these concerns will determine the pace of broader IoT adoption.

Emerging developments focus on creating sensors with reduced power requirements, enhanced communication standards, and deeper artificial intelligence integration for advanced analytics. These innovations will unlock new potential for autonomous decision-making within sensor networks. The convergence of AI with sensor data streams promises breakthroughs in equipment maintenance forecasting, customized medical treatment, and optimized resource allocation.

Predictive Maintenance: Minimizing Downtime and Maximizing OEE

Predictive Maintenance and IoT

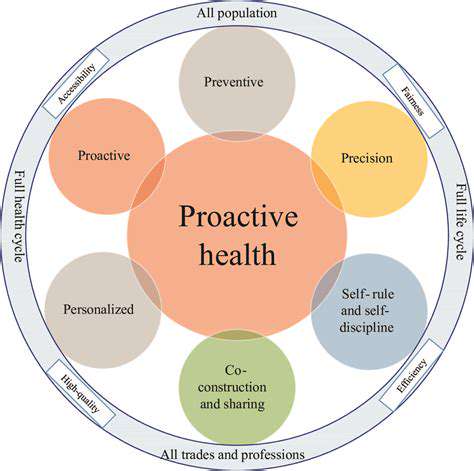

Modern manufacturing strategies increasingly incorporate predictive maintenance through interconnected device networks. This approach enables continuous equipment performance monitoring, allowing potential malfunctions to be addressed before causing operational disruptions. The resulting reduction in unplanned outages directly improves production efficiency while lowering maintenance expenditures.

This methodology relies on integrated sensor networks coupled with advanced analytics platforms. These systems monitor vital operational metrics including mechanical oscillations, thermal readings, force measurements, and power usage patterns to assess equipment condition.

Data Collection and Analysis

The predictive maintenance paradigm centers on comprehensive data gathering and interpretation. Embedded monitoring devices generate extensive operational data streams processed by specialized analysis algorithms. These computational models detect irregular patterns that may indicate developing equipment issues.

This analytical approach provides unprecedented visibility into machinery health, enabling preemptive corrective actions that prevent catastrophic failures and maintain continuous operation. Graphical data representations allow rapid identification and resolution of emerging concerns.

Machine Learning for Anomaly Detection

Advanced pattern recognition algorithms form the backbone of modern predictive maintenance systems. By processing historical operational data, these systems learn to identify subtle deviations from normal performance parameters that human observers might overlook.

This anticipatory capacity allows maintenance activities to be scheduled during optimal periods, minimizing production interference while maximizing asset utilization. The transition from reactive to proactive maintenance represents a fundamental shift in industrial operations.

Improved Equipment Reliability

Predictive methodologies dramatically enhance machinery dependability and operational lifespan. Early identification of potential issues permits timely interventions that prevent major failures. This forward-looking approach reduces replacement costs and lowers total operational expenses.

Continuous performance tracking also generates valuable insights for equipment optimization, informing both maintenance protocols and future design improvements. This feedback mechanism drives ongoing enhancements in manufacturing efficiency.

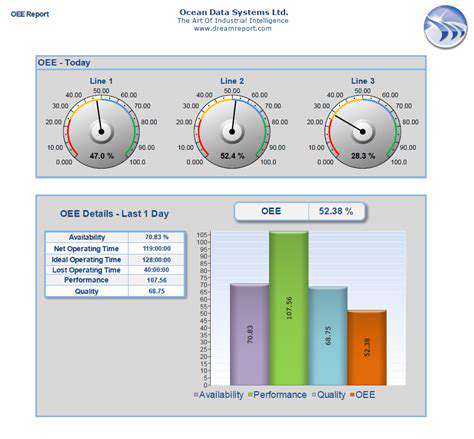

Reduced Downtime and Increased OEE

The most significant benefit of predictive maintenance lies in its ability to virtually eliminate unscheduled production stoppages. By preventing unexpected equipment failures, manufacturers achieve higher operational continuity, directly translating to improved production metrics. The financial impact extends beyond simple outage reduction.

Enhanced equipment performance and reduced maintenance frequency contribute to more stable production processes, maximizing return on capital investments. These cumulative benefits create substantial competitive advantages in manufacturing operations.

Human anatomy provides natural measurement tools that automatically adjust to individual physiology. This biological scaling ensures portion sizes naturally correspond to metabolic requirements - people with larger body frames possess proportionally larger hands that measure appropriately sized servings. Unlike standardized measuring implements, this method accounts for personal nutritional needs while maintaining simplicity in any environment.

OEE Enhancement through IoT-Enabled Data Analysis

Real-time Data Acquisition and Monitoring

IoT implementation enables continuous performance data collection from production assets, creating comprehensive operational visibility. This monitoring capability serves as an advanced warning mechanism, allowing rapid response to developing issues. Immediate data availability significantly decreases equipment outages and boosts production efficiency metrics. Interactive visualization tools transform raw data into actionable intelligence for operational teams.

Detailed performance analysis becomes possible through continuous data streams. Operational personnel can detect abnormal patterns and make timely adjustments to processes and machine configurations. This proactive monitoring approach forms the foundation of effective efficiency improvement programs.

Predictive Maintenance Strategies

Networked sensors collect mechanical vibration data, thermal readings, and other critical performance indicators. Sophisticated analysis software processes this information to forecast potential equipment issues. This anticipatory capability enables maintenance planning that minimizes production interference.

The transformative potential of predictive analytics lies in its ability to schedule necessary repairs during planned downtime periods. This strategic approach prevents unexpected production losses and maintains consistent output levels.

Optimized Maintenance Schedules

Analysis of operational data and predictive models allows for refined maintenance planning. This optimization leads to more efficient resource allocation and elimination of unnecessary servicing activities. Precisely timed maintenance interventions are essential for maximizing equipment availability. This targeted approach substantially reduces the likelihood of unplanned stoppages while ensuring maintenance occurs at optimal intervals.

Data-driven maintenance scheduling represents a significant operational advantage. The resulting reduction in unexpected downtime contributes directly to improved production consistency and output volumes.

Enhanced Process Control and Optimization

IoT systems provide comprehensive operational metrics including energy utilization, material consumption, and production rates. These insights identify potential process improvements. Data analysis enables manufacturing refinements that reduce inefficiencies and boost productivity. This analytical approach generates measurable cost reductions and improves financial performance.

Continuous process monitoring facilitates rapid identification of production bottlenecks. For organizations pursuing operational excellence, this capability represents a powerful tool for efficiency gains.

Improved Safety and Worker Productivity

IoT implementations monitor critical safety parameters including equipment speeds, pressure levels, and temperature readings. Continuous surveillance enables immediate hazard detection, strengthening safety measures. Early warning mechanisms play a vital role in accident prevention and workforce protection.

Real-time operational data also enhances worker effectiveness. Improved process visibility and immediate feedback reduce error rates and increase task efficiency. By providing clear equipment status indicators, IoT systems empower personnel to make better operational decisions, driving productivity gains.