The Growing Need for Supply Chain Resilience in Today's Dynamic Environment

Optimizing Efficiency and Responsiveness

Modern businesses operate in an environment where supply chains must be both efficient and responsive to remain competitive. Organizations are waking up to the reality that optimizing their supply chains isn't just about cutting costs - it's about creating strategic advantages. What separates thriving companies from struggling ones is their ability to streamline operations, slash delivery times, and control expenses in our rapidly evolving marketplace. This requires moving beyond outdated, compartmentalized methods toward holistic approaches powered by data analytics across the entire value network.

Forward-thinking enterprises are adopting cutting-edge technologies like robotic process automation, machine learning, and advanced forecasting models. These innovations provide unprecedented transparency into stock levels, shipping paths, and possible interruptions. When businesses harness these data-driven insights, they gain the power to anticipate challenges before they arise and allocate resources more intelligently, building supply chains that can withstand disruptions.

Addressing Global Disruptions and Uncertainties

Today's interconnected global economy means supply chains span continents, exposing them to countless potential breakdowns. Political conflicts, extreme weather events, health crises, and market volatility can all throw carefully planned logistics into chaos. The most successful organizations are those that build flexibility into their supply networks, creating systems that can pivot quickly when unexpected challenges emerge.

Smart companies are responding by developing multiple sourcing options, cultivating deeper partnerships with vendors, and creating robust backup plans. Equally important is establishing open communication channels with all supply chain participants to enable swift problem-solving when issues occur.

Enhancing Sustainability and Ethical Practices

Today's consumers are more environmentally and socially conscious than ever before, demanding responsible practices throughout product lifecycles. Businesses face growing pressure to reduce ecological impacts, minimize resource waste, and guarantee fair treatment of workers across their entire operation network.

Implementing green initiatives like carbon footprint reduction and product lifecycle extension programs has become business-critical. Equally vital is maintaining ethical standards - ensuring living wages, safe workplaces for all employees, and positive community impacts wherever operations touch down.

The Role of Technology in Modern Supply Chains

Digital transformation is reshaping supply chain management, creating new possibilities for efficiency, transparency, and adaptability. From smart warehousing solutions to advanced transportation management platforms, technology now enables real-time tracking of goods, disruption prediction, and delivery route optimization. The strategic implementation of these tools allows companies to base decisions on hard data rather than guesswork, resulting in supply networks that are both more effective and more responsive to change.

Sophisticated analytics and machine learning applications help businesses forecast needs more precisely, balance inventory more effectively, and spot potential risks earlier. This analytical approach leads to smarter choices, reduced waste, and deeper understanding of the complex factors influencing supply chain performance.

Optimizing Inventory Management and Demand Forecasting

Optimizing Inventory Levels

Smart inventory control forms the backbone of any resilient supply network. Advanced analytical systems can process years of sales records, seasonal patterns, and macroeconomic indicators to generate remarkably accurate demand predictions. This predictive power enables businesses to maintain ideal stock quantities, avoiding both shortages and costly overstock situations.

These systems go beyond basic forecasting to enable proactive inventory adjustments. Sophisticated algorithms can detect emerging trends, like unexpected surges in product popularity or supply delays, allowing businesses to rebalance their inventories before problems escalate. This forward-looking approach dramatically boosts operational efficiency while reducing vulnerability to disruptions.

Improving Demand Forecasting Accuracy

While traditional forecasting relied heavily on historical data and human intuition, modern methods incorporate diverse data streams including social media activity, industry shifts, and even meteorological data. This multidimensional analysis produces forecasts with far greater precision and nuance.

By processing live data feeds and continuously learning, these systems can adapt to demand fluctuations with remarkable speed. In today's fast-moving markets where consumer preferences change overnight, this adaptability gives businesses a crucial competitive edge in meeting customer needs effectively.

Predictive Maintenance for Equipment

Modern supply chains benefit tremendously from equipment monitoring systems that analyze sensor data to predict maintenance needs before failures occur. This proactive approach prevents costly operational downtime by scheduling maintenance at optimal times, keeping supply chain infrastructure running smoothly.

Enhanced Supplier Relationship Management

Digital platforms now enable deeper collaboration with suppliers through performance analytics that identify both risks and opportunities. These insights help negotiate better terms, strengthen partnerships, and ensure consistent quality and timely deliveries - all critical for maintaining resilient supply networks.

Real-time Tracking and Visibility

Advanced monitoring systems provide minute-by-minute visibility into shipment locations and statuses across global supply networks. This real-time awareness enables rapid response to delays, optimized routing, and effective risk management while keeping customers informed about order progress.

Personalized Customer Experiences

By analyzing customer behavior patterns and preferences, supply chain systems can now tailor product offerings, delivery options, and communications to individual needs. This personal touch builds stronger customer relationships and drives business growth through enhanced satisfaction and loyalty.

Automating Risk Assessment and Mitigation Strategies

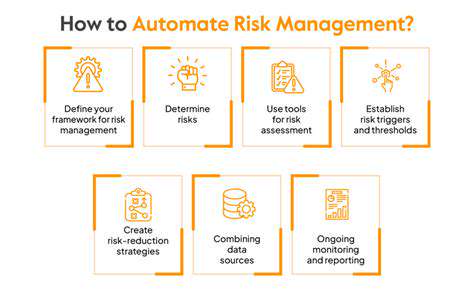

Automating Risk Identification

Modern risk detection systems process data from security logs, vulnerability databases, and threat intelligence feeds to rapidly identify potential risks. This automated approach enables security teams to respond to threats faster and implement protective measures more efficiently.

By analyzing both historical patterns and current events, these systems can spot emerging threats that might escape manual detection, providing crucial early warnings.

Defining Risk Criteria

Effective automated risk assessment depends on establishing clear definitions for risk severity levels. Well-defined risk parameters ensure consistent, objective evaluations that support better prioritization and decision-making.

Standardized risk templates help maintain assessment consistency while ensuring all relevant factors receive proper consideration.

Prioritizing Risks

Automated tools evaluate identified risks based on probability and potential impact, allowing security teams to focus first on the most critical vulnerabilities. This targeted approach maximizes the effectiveness of security resources while minimizing unnecessary expenditures.

Integrating with Existing Systems

Modern risk assessment platforms connect seamlessly with security information systems, vulnerability management tools, and other operational platforms. This integration eliminates data silos and provides a comprehensive view of organizational security posture.

Generating Reports and Dashboards

Automated systems produce clear, visually engaging reports that communicate risk findings effectively to stakeholders. Regular reporting provides leadership with current security status updates to support informed decision-making.

Mitigating Risks

Advanced systems don't just identify risks - they recommend specific mitigation strategies like security patches, control implementations, or policy updates. These automated recommendations save valuable time that would otherwise be spent developing solutions from scratch.

Continuous Monitoring and Improvement

The most sophisticated tools provide ongoing surveillance of the threat landscape, automatically updating risk assessments as new vulnerabilities emerge. This constant vigilance is essential for maintaining strong security in our rapidly evolving digital environment.

Enhancing Collaboration and Communication Across the Supply Chain

Improving Visibility and Transparency

Real-time data sharing creates unprecedented transparency across supply networks. Analytical systems aggregate and interpret data from multiple sources, providing comprehensive views of inventory, transportation, and production status. This visibility enables quick, informed decision-making that minimizes delays and optimizes resource use.

Automated alert systems ensure all stakeholders receive critical updates simultaneously, preventing communication gaps that could lead to operational problems.

Streamlining Communication Processes

AI-powered communication tools handle routine inquiries and scheduling, freeing human resources for strategic work. These solutions can also overcome language barriers, facilitating collaboration across global teams while reducing errors common in manual processes.

Optimizing Inventory Management

Predictive analytics transform inventory management by forecasting demand patterns with remarkable accuracy. By analyzing historical data and current trends, these systems help businesses maintain optimal stock levels, avoiding both shortages and costly overstock situations.

These systems can also detect subtle shifts in customer preferences, enabling businesses to adjust inventory strategies accordingly and deliver more personalized service.

Facilitating Collaboration Platforms

Digital collaboration hubs centralize information sharing across supply networks, from suppliers to end customers. These platforms often include automated features for order processing, invoicing, and payment tracking that reduce administrative burdens.

Enhancing Decision-Making Capabilities

Advanced analytics provide deep insights into supply chain operations, enabling data-driven decisions. These systems can identify potential risks early, allowing proactive mitigation measures that minimize operational impacts.

Improving Forecasting Accuracy

Sophisticated algorithms analyze multiple data streams - including market trends and economic indicators - to generate highly accurate demand forecasts. This precision enables better inventory, production, and transportation planning.

Continuous learning capabilities allow these systems to refine their forecasts based on real-world results, maintaining accuracy even as market conditions change.