Improving Inventory Management and Supply Chain Optimization

Optimizing Stock Levels

Maintaining optimal stock levels is crucial for efficient inventory management. Having too much inventory ties up capital, increases storage costs, and risks obsolescence. Conversely, insufficient stock can lead to lost sales and dissatisfied customers. Implementing a robust forecasting system, considering historical sales data, seasonal trends, and potential disruptions, is essential for accurately predicting future demand and adjusting stock levels accordingly.

Implementing a system for real-time inventory tracking allows for proactive adjustments to stock levels, minimizing the risk of stockouts or overstocking. This data-driven approach ensures that the right amount of inventory is available at the right time, ultimately improving operational efficiency and reducing costs.

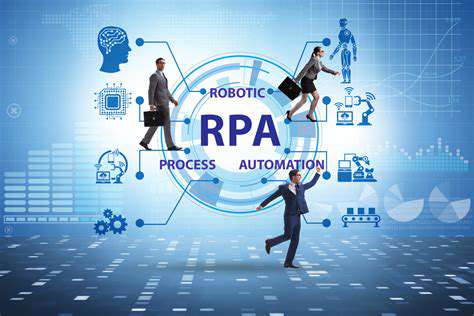

Implementing Automated Systems

Integrating automated inventory management systems can significantly improve efficiency and accuracy. These systems can track stock levels in real-time, automate reordering processes, and provide detailed reports on inventory performance. Implementing such systems streamlines the entire process, reducing manual errors and freeing up valuable time for other tasks.

Automated systems often offer advanced features such as barcode scanning, RFID technology, and predictive analytics, further enhancing inventory control and minimizing potential risks.

Improving Forecasting Accuracy

Accurate forecasting is the cornerstone of effective inventory management. By analyzing historical sales data, market trends, and seasonal patterns, businesses can develop more precise predictions of future demand. This data-driven approach minimizes the risk of stockouts or overstocking, leading to improved customer satisfaction and reduced operational costs.

Utilizing sophisticated forecasting techniques, such as time series analysis or machine learning algorithms, can enhance the accuracy of predictions and ensure that stock levels are optimally aligned with projected demand.

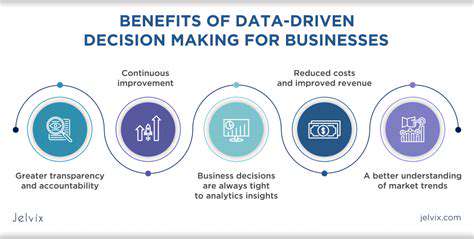

Utilizing Data Analytics

Data analytics plays a vital role in understanding inventory patterns and trends. Analyzing sales data, customer behavior, and external factors can help identify potential issues and opportunities related to inventory management. This data-driven approach allows businesses to make informed decisions, optimize stock levels, and reduce waste.

By leveraging data visualization tools and dashboards, businesses can gain a clear understanding of their inventory performance, identify areas for improvement, and optimize their overall inventory strategy.

Streamlining Order Fulfillment

Efficient order fulfillment is essential for maintaining customer satisfaction and minimizing delays. Optimizing warehouse layouts, implementing efficient picking and packing procedures, and utilizing technology to streamline order processing can significantly improve order fulfillment times.

Utilizing advanced warehouse management systems (WMS) can further enhance order fulfillment by automating tasks, tracking inventory movements, and optimizing picking routes. This leads to faster order processing and reduced order cycle times.

Optimizing Warehouse Space

Effective warehouse space utilization is crucial for maximizing storage capacity and minimizing operational costs. Implementing strategies such as optimizing storage layouts, utilizing vertical space, and implementing efficient picking and packing procedures can significantly improve warehouse efficiency. By maximizing the use of available space, businesses can reduce storage costs and enhance overall operational efficiency.

Employing advanced warehouse management systems (WMS) can optimize warehouse space utilization by tracking inventory locations and optimizing picking routes, leading to a more efficient and productive warehouse environment.

Implementing Inventory Control Policies

Establishing clear and concise inventory control policies is vital for maintaining order and consistency. These policies should define procedures for receiving, storing, tracking, and issuing inventory. Implementing clear protocols ensures accountability, minimizes errors, and promotes a consistent inventory management process.

Regular audits and reviews of inventory control policies are essential for ensuring that they remain relevant and effective in addressing evolving business needs and maintaining optimal inventory management.