Transforming Medical Supply Networks Through Smart Systems

Modernizing Supply Chain Operations

Contemporary healthcare systems depend on meticulously optimized supply networks. Precise coordination of medical resources—from pharmaceuticals to critical equipment—directly influences both patient outcomes and institutional performance. Interruptions in the supply flow, critical item deficiencies, and imprecise stock monitoring can profoundly affect clinical results and facility operations. Healthcare administrators consequently require adaptive systems capable of managing goods movement from acquisition to bedside delivery.

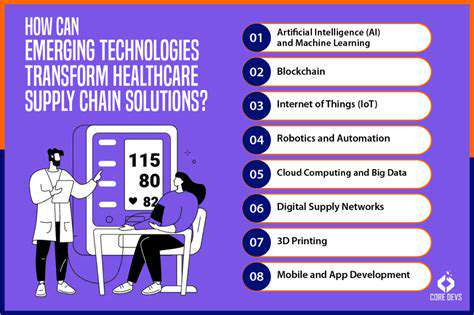

Modernizing these operations requires strategic implementation of digital solutions across all workflow stages. Automated purchasing platforms combined with live inventory monitoring can dramatically decrease human errors, refine demand predictions, and guarantee immediate availability of vital supplies. Such technological integration helps curb resource wastage, lower expenses, and elevate overall facility productivity.

Advanced Stock Control Solutions

Precision in inventory oversight remains non-negotiable for medical institutions. Maintaining exact records of available supplies, medications, and devices prevents treatment interruptions and safeguards patient welfare. This forward-looking methodology simultaneously curtails financial waste from excessive stockpiling or expired merchandise. Multi-site inventory synchronization emerges as a cornerstone of effective resource management.

Sophisticated stock management platforms offer panoramic visibility of supply levels, anticipate consumption patterns, and trigger automatic replenishment. Beyond operational improvements, these systems critically affect clinical safety and therapeutic effectiveness. By virtually eliminating shortage risks, hospitals can sustain uninterrupted access to medical necessities—ensuring prompt patient intervention.

Moreover, these intelligent systems enable lean inventory approaches that minimize storage footprints and product obsolescence. Such methodologies further enhance fiscal responsibility while optimizing resource deployment.

Revolutionizing Acquisition Strategies

Procurement operations form the backbone of consistent, high-caliber medical supply chains. Rapid, efficient sourcing of necessary items represents a fundamental healthcare operational competency. Developing dependable vendor partnerships, negotiating advantageous agreements, and standardizing purchase protocols creates a framework that must flex with evolving clinical demands.

Digital procurement solutions transform the acquisition continuum—from initial requests through final distribution. Electronic systems foster transparent communication, enhanced tracking, and reduced paperwork burdens. Automating these processes liberates clinical staff to concentrate on patient care rather than administrative tasks.

Contemporary procurement frameworks also accommodate sustainable practices through ethical sourcing and ecological consciousness. This dual focus benefits both environmental conservation and institutional reputation building.

Rigorous quality assurance protocols—including compliance verification and supplier audits—ensure medical products meet stringent safety standards. Such vigilance preserves patient well-being while maintaining operational dependability.

Anticipatory Analytics for Smarter Inventory Control

Precision Demand Projection

Predictive modeling significantly refines inventory forecasting accuracy. By synthesizing historical patterns, environmental variables, and algorithmic analysis, organizations generate remarkably precise demand projections. This enhanced predictive capacity mitigates both shortage scenarios and surplus accumulation—yielding substantial financial benefits. Accurate forecasting enables optimal stock positioning, ensuring product availability aligns perfectly with consumption patterns while minimizing storage expenses.

Incorporating real-time sales data and purchasing behaviors creates dynamic forecasting models that adjust to market fluctuations. This responsive analytical approach maintains supply-demand equilibrium despite variable conditions, guaranteeing resource accessibility when and where required.

Balanced Stock Optimization

Analytical tools facilitate ideal inventory equilibrium—satisfying consumer needs without excessive warehousing costs. Evaluating consumption history and projected requirements helps determine perfect stock quantities that prevent shortages while controlling carrying expenses. This optimization accounts for delivery timelines, purchase volumes, and contingency reserves—creating a comprehensive inventory methodology.

Early identification of supply chain vulnerabilities enables preemptive countermeasures. Predictive systems allow inventory adjustments before potential disruptions materialize, creating agile management frameworks that maximize efficiency despite market volatility.

Transparent Supply Networks

Analytical forecasting illuminates potential supply chain interruptions and choke points. Pattern recognition in historical data helps anticipate delays, vendor shortages, or demand spikes. This predictive visibility enables proactive resolution before operational impacts occur—maintaining seamless goods movement.

Risk assessment capabilities represent a crucial analytical benefit. Addressing supply chain weaknesses preemptively minimizes disruption likelihood, ensuring product availability and customer contentment. Comprehensive visibility across the entire supply continuum—from materials sourcing to end-user delivery—supports informed decision-making and effective risk reduction.

Preventative Disruption Management

Predictive analytics empower organizations to identify supply chain vulnerabilities and implement preventative safeguards. Historical pattern analysis helps anticipate shipping delays, supplier challenges, or unexpected demand fluctuations. This forward-looking perspective allows inventory strategy adjustments before operational disturbances escalate.

Proactive risk mitigation builds resilient supply networks. Early issue detection and resolution minimizes production, distribution, and customer service impacts—enhancing efficiency, reducing costs, and boosting profitability. Integrated predictive systems enable dynamic response capabilities that maintain competitive advantage amid market changes.

AI-Driven Transportation and Distribution Networks

Intelligent Route Optimization

Sophisticated transportation network enhancement proves essential for organizations pursuing logistical efficiency and cost reduction. This requires meticulous examination of existing routes, delivery timetables, and transport modalities to pinpoint improvement opportunities. Data-driven analysis and predictive algorithms optimize routing to decrease fuel usage, shorten transit durations, and boost overall performance. Dynamic route adjustments incorporate real-time variables like traffic congestion, weather systems, and operational updates.

Transport optimization extends comprehensively to fleet operations—including maintenance planning, operator performance metrics, and fuel economy. Advanced fleet management generates notable cost reductions and environmental benefits through telematics solutions that provide live vehicle tracking, enabling predictive maintenance and adaptive routing.

Comprehensive Logistics Strategy

Holistic logistics planning manages product movement from origin to consumption point, encompassing storage solutions, inventory control, and order processing. Strategic logistics frameworks ensure punctual deliveries, cost containment, and customer satisfaction through integrated analysis of demand projections and supply chain weaknesses.

This multidimensional planning approach synchronizes transportation methods, warehouse capacities, and stock levels to guarantee seamless order completion despite market variability.

Smart Storage Solutions

Effective stock control remains fundamental to logistical excellence. Just-in-time inventory methodologies demonstrate how precise stock monitoring, demand forecasting, and storage optimization can minimize overhead while maintaining service levels. This delicate balance between product availability and storage economics requires sophisticated tracking systems.

Warehouse optimization focuses on space utilization, streamlined picking protocols, and product security. Modern warehouse management systems (WMS) enhance accuracy and speed while reducing fulfillment errors through digital automation.

Digital Transformation in Logistics

Technological integration revolutionizes transportation and distribution efficiency. Advanced tracking solutions, GPS navigation, and real-time analytics enable shipment monitoring, route optimization, and delay prediction—empowering data-driven decision making that strengthens supply chain resilience.

Automated platforms and digital interfaces simplify order processing, inventory oversight, and stakeholder communication. Technological adoption fosters operational transparency, improves process visibility, and elevates customer service benchmarks throughout the supply network.