A Game Changer for Industrial Efficiency

The industrial world is seeing remarkable benefits from predictive maintenance strategies. Instead of waiting for machines to break down, companies now use data to anticipate problems. This approach prevents costly interruptions and keeps operations running smoothly. The savings go beyond repair costs—it's about maintaining steady production without unexpected stops.

At its core, this method relies on understanding equipment behavior. By knowing when a machine might need attention, maintenance can be planned for times when it won't disrupt work. This thoughtful scheduling makes better use of both equipment and staff time.

Data Collection and Analysis: The Foundation of Predictive Maintenance

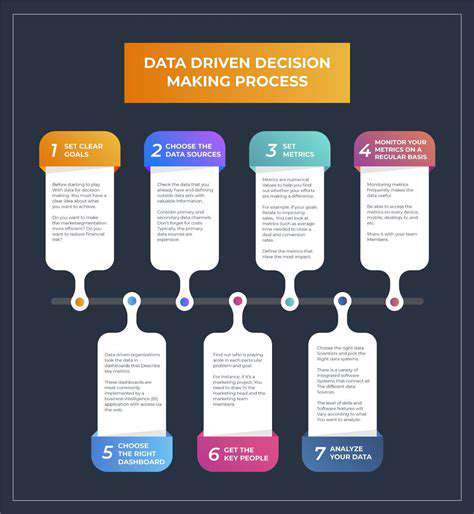

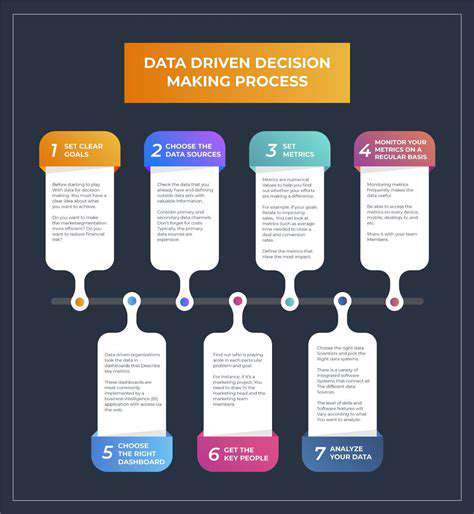

Making predictions about equipment requires gathering lots of information—from sensor readings to maintenance histories. Good data leads to accurate forecasts, helping maintenance teams make smart decisions about when and where to focus their efforts.

Modern analysis tools can spot patterns humans might miss. These systems learn from experience, becoming better at predicting problems the more data they process.

Identifying Anomalies and Predicting Failures

The real power lies in detecting small changes that signal bigger issues. Maybe a motor is vibrating slightly more than usual, or a pump is running a few degrees warmer. These subtle signs, combined with historical data, allow for remarkably accurate predictions about when maintenance will be needed.

Improved Equipment Reliability and Performance

When machines receive care before problems escalate, they last longer and work better. This preventive approach means fewer breakdowns, more consistent output, and lower overall costs. Equipment that's well-maintained simply performs better over time.

Reduced Maintenance Costs and Downtime

The financial benefits are clear—emergency repairs cost more than planned maintenance. By avoiding unexpected failures, companies save money while keeping production on schedule. It's a win-win for budgets and productivity.

Enhanced Safety and Operational Efficiency

Predictive maintenance makes workplaces safer by catching potential hazards early. It also streamlines operations by ensuring maintenance happens at the best possible times. Spotting problems before they become dangerous protects both workers and equipment.

Integration with Existing Systems and Processes

Adding predictive capabilities to existing operations requires careful planning. The goal is to make the new system work smoothly with current processes while keeping all data secure and reliable.

Challenges and Considerations in IoT Implementation

Security Vulnerabilities

Connecting building systems to networks introduces security risks that can't be ignored. Hackers might try to access temperature controls, security systems, or other critical functions. Strong protections like encryption and multi-step verification are essential to keep smart buildings safe from digital threats.

The more devices connected to a network, the more potential entry points exist for attackers. This complexity requires security measures at every level—individual devices, the network itself, and any cloud services used.

Data Management and Privacy

Smart buildings generate enormous amounts of information about how spaces are used. While this data helps improve operations, it must be handled carefully to protect people's privacy. Clear policies about what's collected and how it's used help build trust with building occupants.

Privacy laws in different regions set strict rules about personal data. Following these regulations isn't just about avoiding fines—it's about respecting the people who live and work in these spaces.

Interoperability and Standardization

One major hurdle is getting equipment from different manufacturers to work together smoothly. Without common standards, integrating new devices can be difficult and expensive. The industry needs agreed-upon ways for systems to communicate to make smart buildings truly flexible.

This lack of standardization can limit options when upgrading or expanding systems. Open standards would allow building owners to choose the best solutions without worrying about compatibility issues.

Scalability and Future-Proofing

Smart building technology needs to grow and adapt over time. Systems designed today should accommodate new devices and capabilities that emerge in coming years. Planning for expansion from the beginning prevents costly overhauls later.

Technology changes rapidly, so smart building systems must be designed to evolve. Regular updates and a flexible architecture ensure buildings can take advantage of new innovations as they become available.