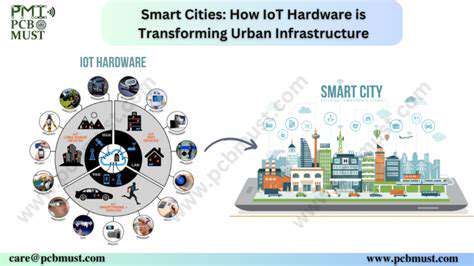

Enhanced Connectivity and Data Transmission

Improved Real-Time Data Transmission

5G's ultra-low latency and high bandwidth capabilities are transforming real-time data transmission, a critical factor for industrial automation. These advancements allow factories to respond swiftly to changing conditions, making rapid adjustments to production lines. Real-time data analysis becomes more powerful, enabling predictive maintenance and proactive solutions that boost efficiency and minimize downtime.

With the capacity to transmit vast amounts of data instantly, sophisticated algorithms and machine learning models can be deployed more effectively. This rapid flow of information empowers operators to make timely decisions, refining production processes and streamlining workflows. As a result, industrial automation systems become more agile and better suited to dynamic environments.

Enhanced Connectivity for Remote Operations

5G's reliable connectivity unlocks new possibilities for remote operations and maintenance. Industrial personnel can now monitor and control equipment from distant locations, significantly broadening their operational scope. This capability is especially valuable in hazardous or hard-to-access areas, reducing risks while maximizing productivity.

Remote monitoring of machinery and processes via 5G connections allows for faster, more precise responses to equipment failures. This accessibility reduces the need for on-site staff during routine maintenance, further improving flexibility and cost-efficiency.

Increased Efficiency in Industrial IoT

The Industrial Internet of Things (IIoT) benefits immensely from 5G's speed and connectivity. Seamless communication between devices, sensors, and systems creates a more integrated industrial ecosystem. Real-time data sharing and analysis lead to smarter decisions and optimized resource allocation.

Data from multiple sources within a facility can be processed quickly, providing deeper insights into production processes. These insights help identify improvement areas and implement targeted optimizations, significantly enhancing operational efficiency.

Improved Collaboration and Communication

5G enables smooth communication among all stakeholders in industrial automation, including operators, engineers, and management. This improved coordination fosters better problem-solving and decision-making. Quick resolutions to production issues become possible, creating a more responsive industrial environment.

Scalability and Flexibility for Future Growth

5G's architecture is inherently scalable, allowing industrial automation systems to adapt to evolving needs. This flexibility is crucial for industries facing changing market demands and technological advancements. The robust 5G infrastructure supports the integration of new technologies into existing systems with minimal disruption.

This future-proofing capability ensures industrial automation remains competitive in a rapidly evolving landscape. Industries can leverage 5G to support both current operations and future innovations.

Enabling Advanced Industrial IoT Applications

Leveraging 5G for Enhanced Connectivity

5G's low latency and high bandwidth are transforming real-time data transmission in industrial settings. These features significantly improve system responsiveness, enabling faster reactions to critical events and reducing downtime. The seamless integration of industrial devices creates a unified platform for data collection and analysis, essential for advanced IIoT applications.

Consider a manufacturing plant that monitors equipment performance in real-time, predicts failures, and automatically optimizes processes. This level of control is only possible with 5G's robust connectivity.

Real-Time Data Analysis and Predictive Maintenance

5G enables the rapid transfer of sensor data from industrial machines, allowing comprehensive monitoring and analysis. This data powers sophisticated predictive maintenance algorithms that can identify potential failures before they occur. By analyzing data patterns, systems can anticipate maintenance needs, schedule repairs proactively, and extend equipment lifespan.

Improved Operational Efficiency and Productivity

5G-powered IIoT applications dramatically improve operational efficiency. Real-time monitoring of production processes allows for immediate adjustments to optimize output and reduce waste. This responsiveness helps manufacturers adapt quickly to market changes and customer demands.

Remote monitoring and control also reduce the need for on-site personnel, potentially lowering labor costs while increasing productivity—particularly valuable for geographically dispersed operations.

Enhanced Safety and Security Measures

5G networks provide secure platforms for transmitting critical industrial data. Their robust security protocols protect sensitive information and ensure process integrity, crucial for preventing costly breaches. Real-time safety monitoring and automated responses to hazards further improve facility safety.

Remote Monitoring and Control Capabilities

5G enables engineers to remotely diagnose and address equipment issues from any location. Real-time data access facilitates proactive troubleshooting, reducing the need for on-site visits and associated costs.

Scalability and Future-Proofing Industrial Operations

5G's scalability allows industrial systems to accommodate growth and new technologies. The network's capacity to handle increasing data volumes ensures operations remain future-proof. This adaptability lets industries integrate new processes without major infrastructure changes, maintaining their competitive edge.